Parallel Routings

My last post about adding a field to the item tracking lines turned out to be very technical, so this time I am doing a post that is completely without any programming or changes to the application.

The topic is parallel routings in Microsoft Dynamics NAV, it is nothing new but something that I get a fair amount of questions about and someone once suggested that I should write a blog post about it. So, here it is! 🙂

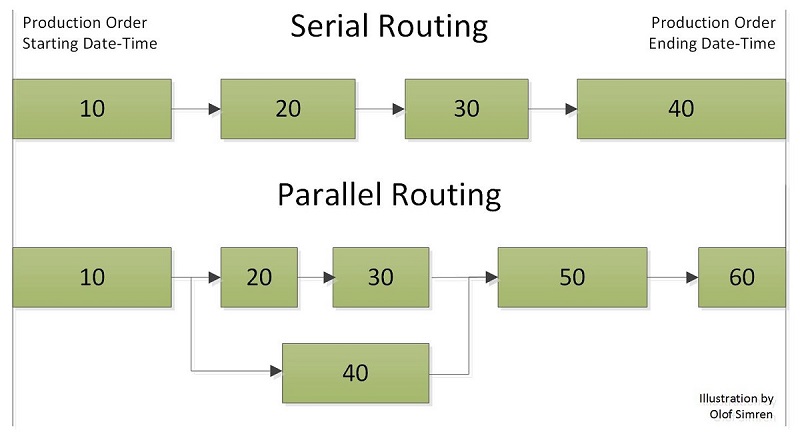

Parallel routings (sometimes also referred to as parallel sequences) are used when multiple manufacturing operations/processes can or is need to be performed simultaneously by routing the material that is being worked on to multiple work centers. The reason to do this can either be to shorten the production lead time or because some of the material is need to be worked on at different work centers. The opposite is a serial routing where each operation takes place after each other (or potentially overlapping).

The two types of routings can be illustrated as below, where the boxes corresponds to operations in a routing that are carried out from left to right.

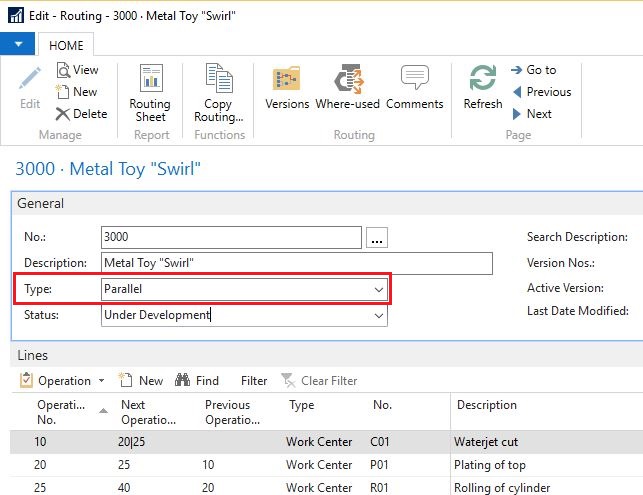

The two above options are in Dynamics NAV defined through the Type field in the header of the routing (where Serial is the default value).

When you setup a parallel routing it is important to display the two fields called Previous and Next Operation on the lines of the routing. Those two fields are used to define where the sequence is going to be split and where it is joined again.

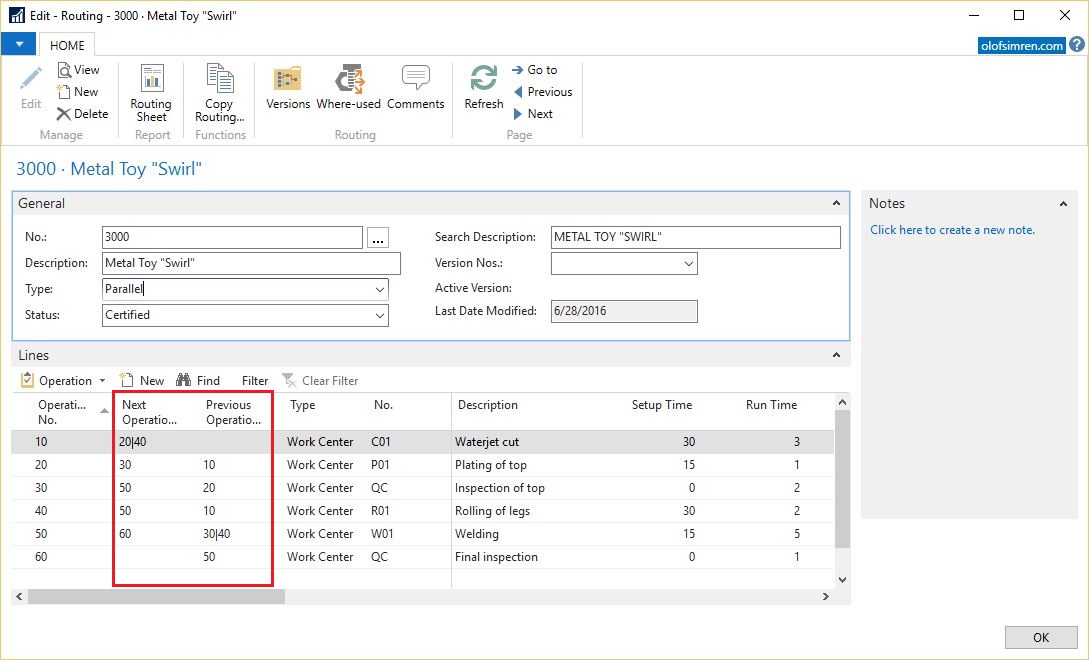

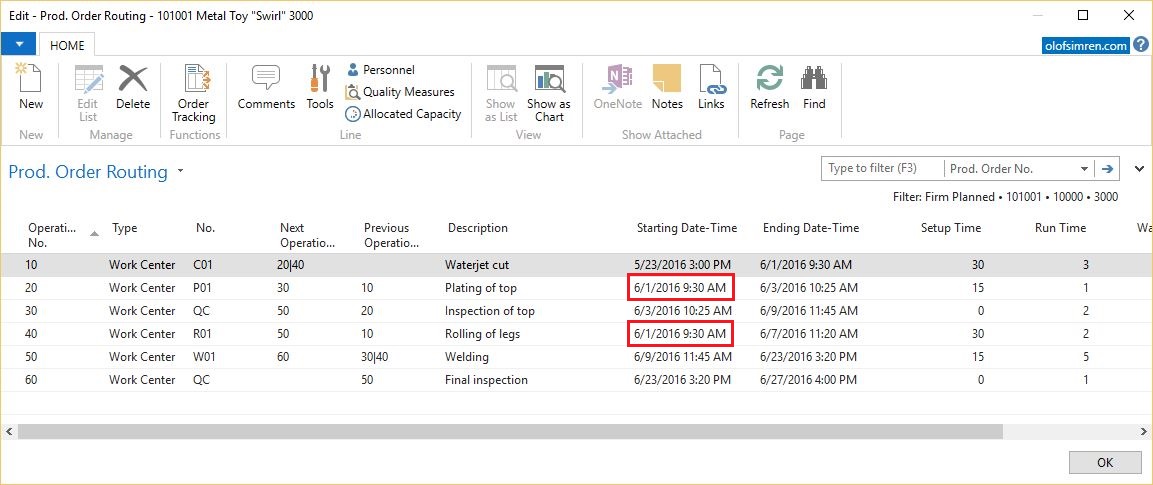

The below example corresponds to the parallel routing in the above illustration, where the first operation (10) is a cutting operation that cuts a metal sheet into multiple parts. The parts are then separated; some goes through a plating process (20) and then an inspection (30) while other parts at the same time are going through a rolling process (40). Then in the end the parts are married in a welding process (50) and a final inspection (60). Note that where the operations are split into two we need to define the previous operation as 10 for both the parallel operations (20 and 40) and for operation 10 we need to define that the next operations are 20 and 40, this is done by listing them with a pipe (|) in between. Then where they join again you need to define the last two operations to be the previous operation (in this case 30|40 for operation 50).

The run time, setup time, wait time, etc. can be setup for each of the operations just like if it was a ‘regular’ serial routing (see production lead time using routings).

How you define your operation numbers are up to you, I kind of like to keep it simple and just assign numbers with an increment of 10. I have seen 20.1, 20.2, etc. for parallel operations as well, and using letters as part of the operations could also be an option.

You can obviously both use work centers and machine centers when setting up parallel routings.

The routing have to start and end with single operations, otherwise you would get an error message when you try to certify the routing.

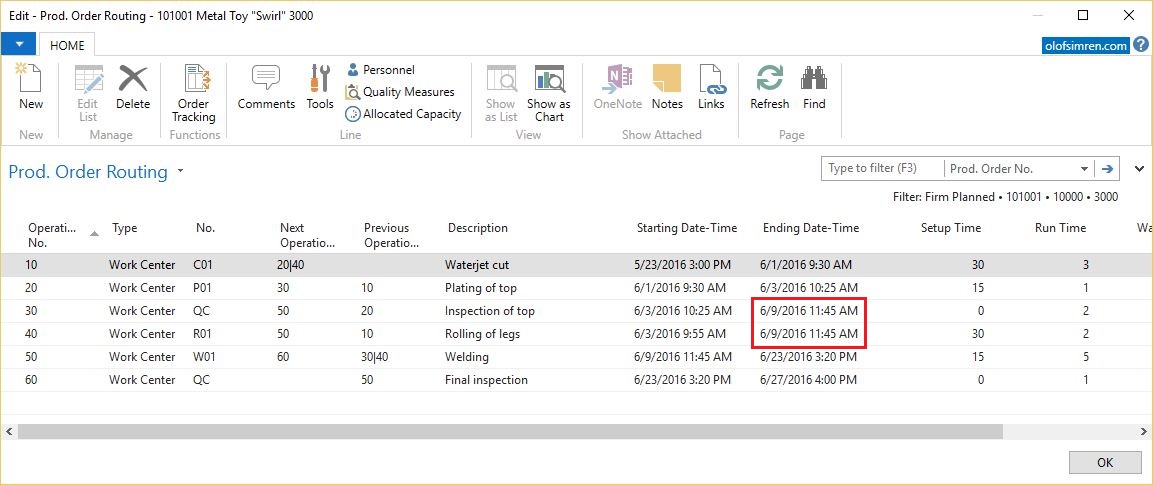

Now we have our routing and we can test it by creating a production order, in the below example I have create a production order for 1000 pieces. I will start with refreshing it with the scheduling direction backwards (this is to me by far the most common way and also how MRP does it), the result is then according to below screenshot. Operation 20 starts right after operation 10, and operation 30 right after operation 20. Then operation 40, which should be carried out simultaneously to 20 and 30 is scheduled to end at the same time as operation 30. This creates what sometimes is referred to a ‘float’ in the beginning of operation 40.

If I then refresh it again with the scheduling direction forward you can see that operation 40 is moved to start at the same time as operation 20, this creates the ‘float’ in the end of the operation 40.

That’s all there is to it, I hope the above clarifies parallel routings in Dynamics NAV and gives an insight to how it can be setup.

During implementations I have also heard users mentioning ‘overlapped’ routings where one operation can start before the previous operation is finished. In Dynamics NAV an overlapping operation can be accomplished in both a parallel and serial routing using the Send Ahead Quantity feature (see my previous blog post about Production Lead Time using Routings for more information about the send ahead quantity). There is no special type of routing called Overlapped in Dynamics NAV.

Have a great day!

Feedback and comments are always welcome, and remember to share this post if you found it useful. 🙂

13 Comments

Leave your reply.