Production Lot Sizes

In the manufacturing part of Microsoft Dynamics NAV there are two Lot Size fields; one is on the item or stockkeeping unit card and the other one is on the routing line. Do you know what they are used for?

Here is an explanation for both of them and a trick how one of them can be applied to a common requirement.

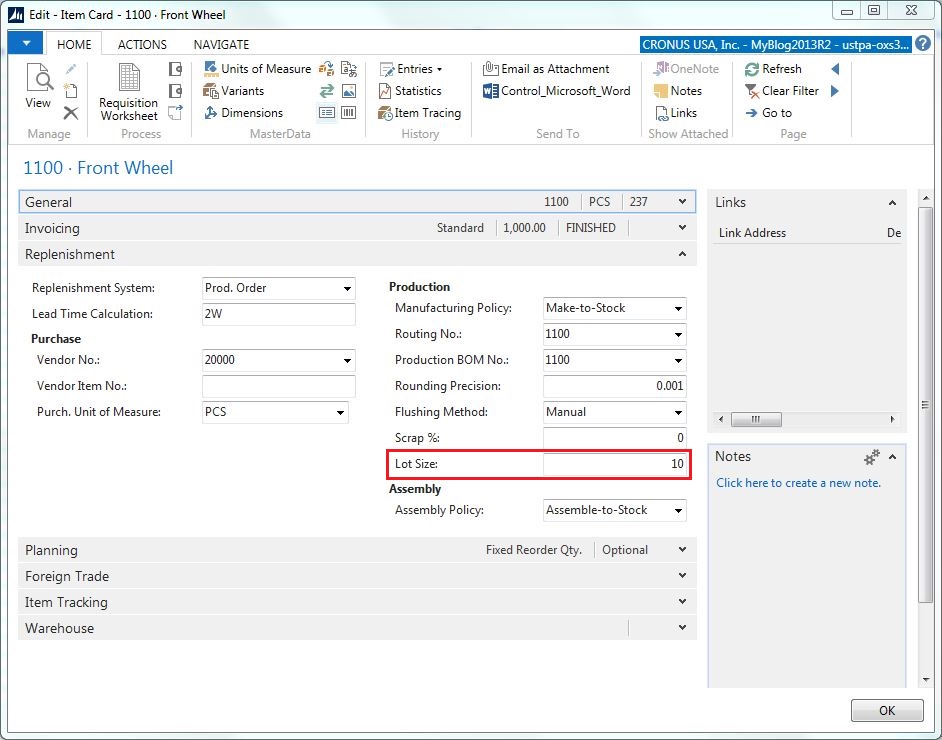

Let’s starts with the Lot Size on the item or stockkeeping unit card, which is found on the replenishment tab.

This field is used during a cost roll-up to calculate the setup costs per unit. It should represent a typical production order size. If the setup time for an operation is 60 minutes and the lot size on the item card is set to 10, then the setup cost corresponds to 6 (60/10) minutes per unit.

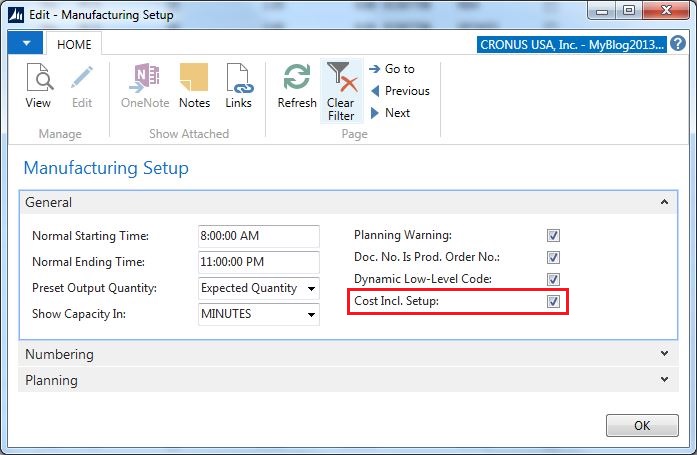

Note that the setup cost is only part of the cost roll-up if this has been activated in the manufacturing setup table through the ‘Cost Incl. Setup’ field.

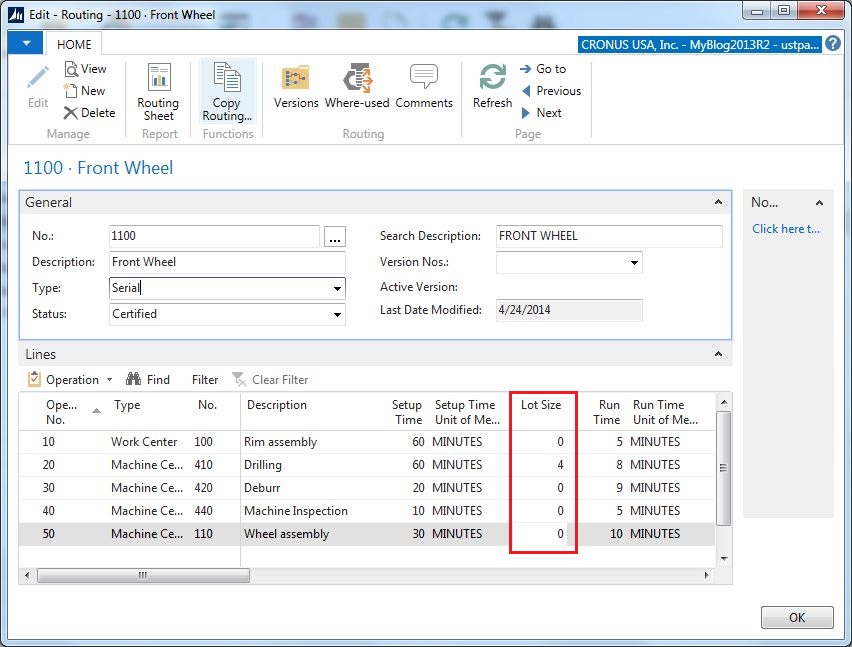

The next Lot Size field is on the routing line, it is a field that is not available on the page so you have to add it first before you can use it.

This field defines how many units that are produced per operation and it has an impact on both the cost roll-up and the scheduling. If an operation is set to 8 minutes and the lot size is 4 then it takes 2 minutes per unit and this is what the cost-rollup will be based on as well. If this field is left as 0 then Dynamics NAV assume that it should be 1.

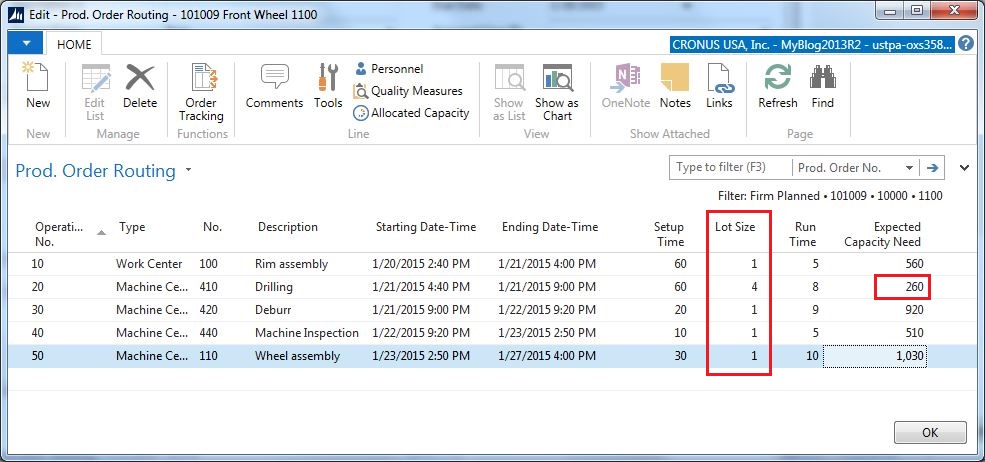

The lot size field in the routing also exists on the production order routing (it gets transferred here from the routing during the refresh of the production order), and as with the routing line you will have to add it to the page to have it displayed. Below is the production order routing for 100 units, as you can see the expected capacity needed for operation 20 is 260 minutes (60 + (8 / 4 * 100)). You can also see that the operations that had a 0 lot size in the routing gets a lot size equal to 1 on the production order routing.

Note; the capacity does not recalculate if a user updated the lot size on the production order routing line, in order for it to recalculate you have to validate the run time or setup time.

Now to the trick for the common requirement; you can use the lot size field on the routing to define the throughput as units per time instead of time per unit. So if the customer says an operation is doing 150 pieces per minute you don’t have to enter this as 0.00667 minutes, you can enter 1 in the run time and put 150 in the lot size. Very useful!

14 Comments

Leave your reply.