Dimensions on Production Orders

The dimensions involved in posting production orders are a bit interesting. It is interesting since there is a slight difference between on how they behave compared to other parts of Microsoft Dynamics NAV (like the sales and purchase orders). It can be argued what is right and wrong, but knowing how it works in standard Dynamics NAV is requirement for setting a system that is easy to work with and provides correct reportable and understandable data. As an example; if you have default dimensions on the items and set them up with the ‘Value Posting’ equal to ‘Same Code’ and you mix items with different default dimension values on a production order you will not be able to post it (this is a very common mistake).

An example of how it is working:

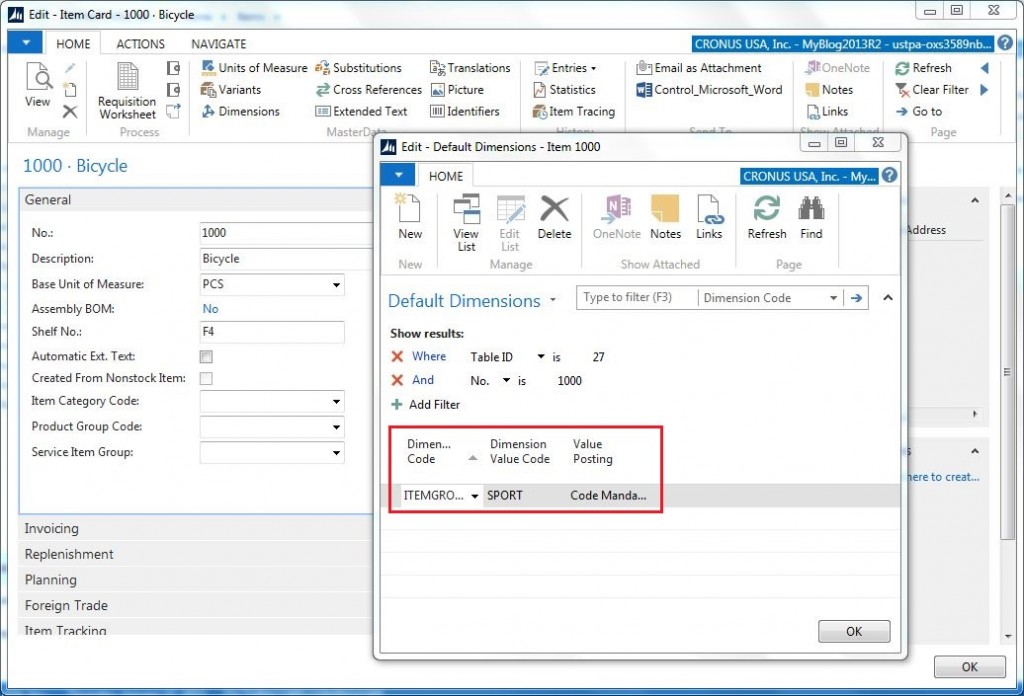

We have a dimension called ‘ITEMGROUP’ for the items, we default the ‘ITEMGROUP’ dimension value on the Bicycle we are producing to be ‘SPORT’ (e.g. sport products).

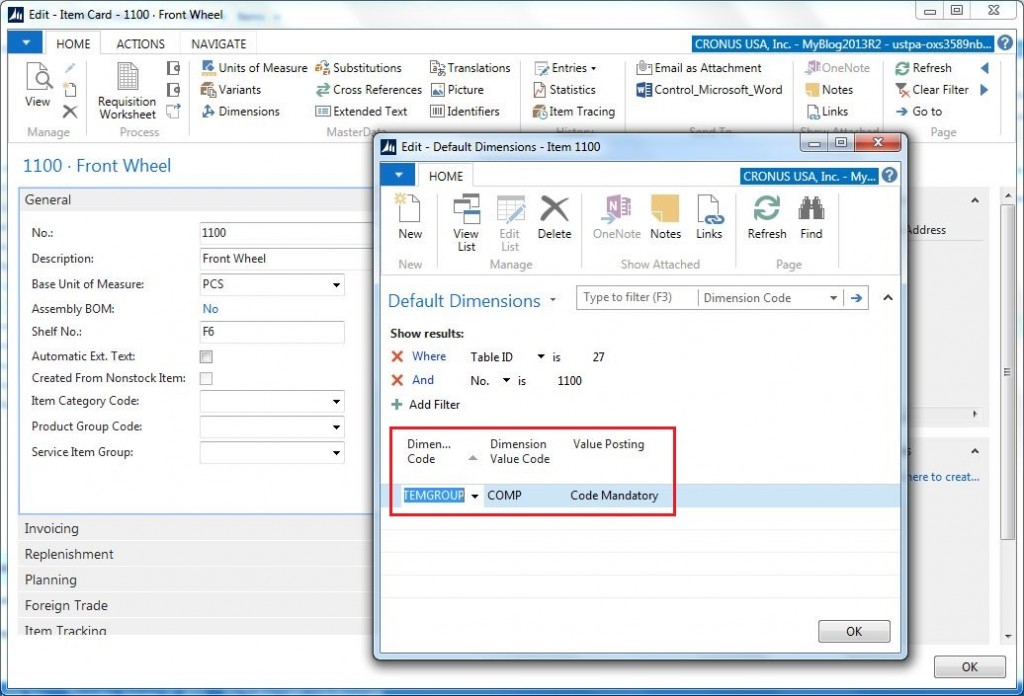

We then default the ‘ITEMGROUP’ dimension value for the components that goes into making the Bicycle as ‘COMP’ (e.g. components).

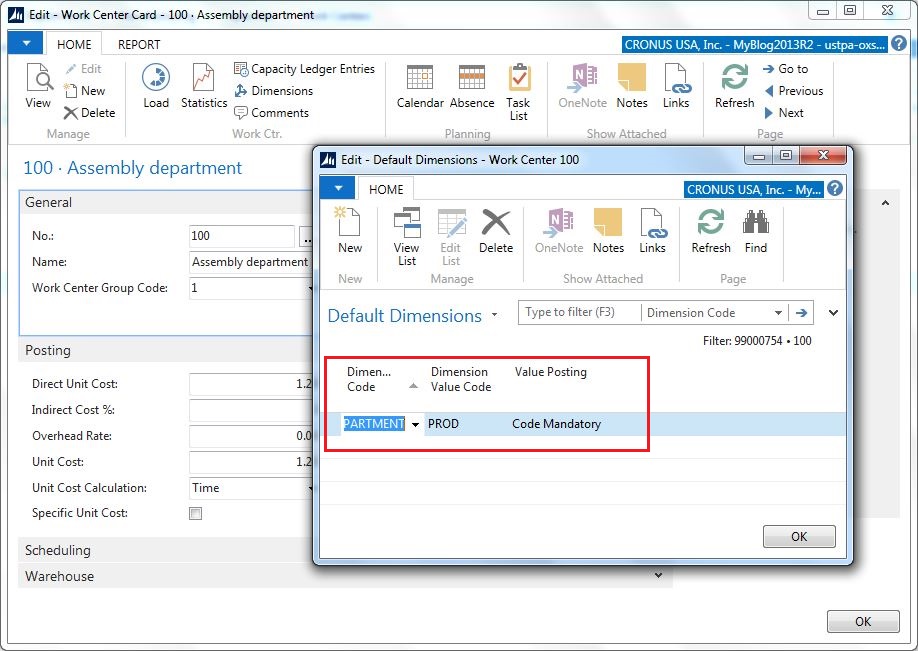

Work Centers also have dimensions, in our example we default the ‘DEPARTMENT’ to ‘PROD’ (e.g. production) for the work center where the production is done (e.g. the assembly department). Note that machine centers do not have dimensions but will inherit the dimensions from the related work center during postings.

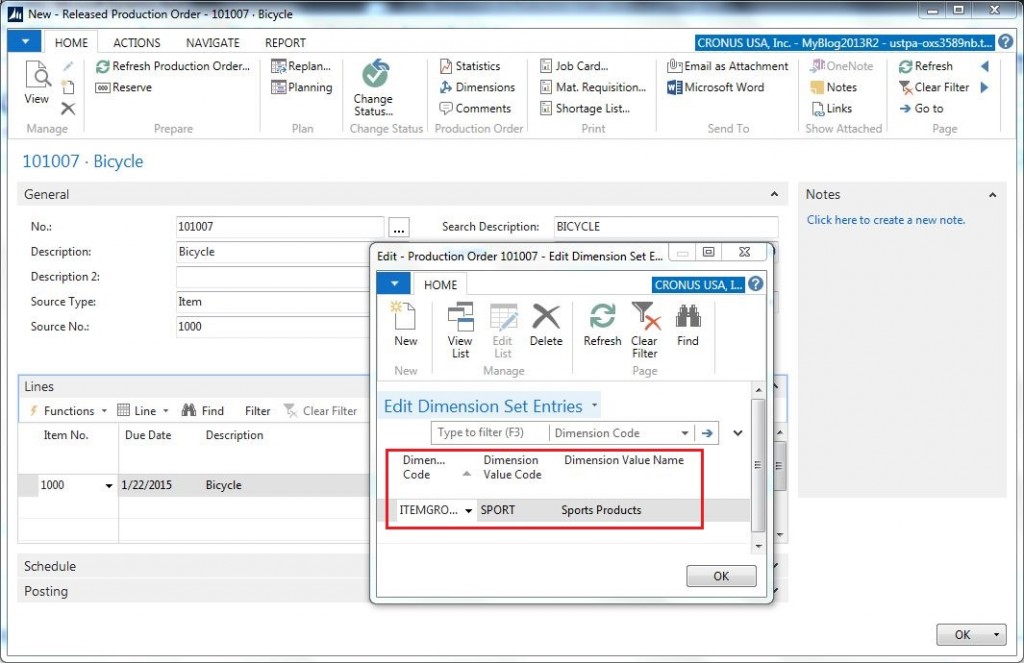

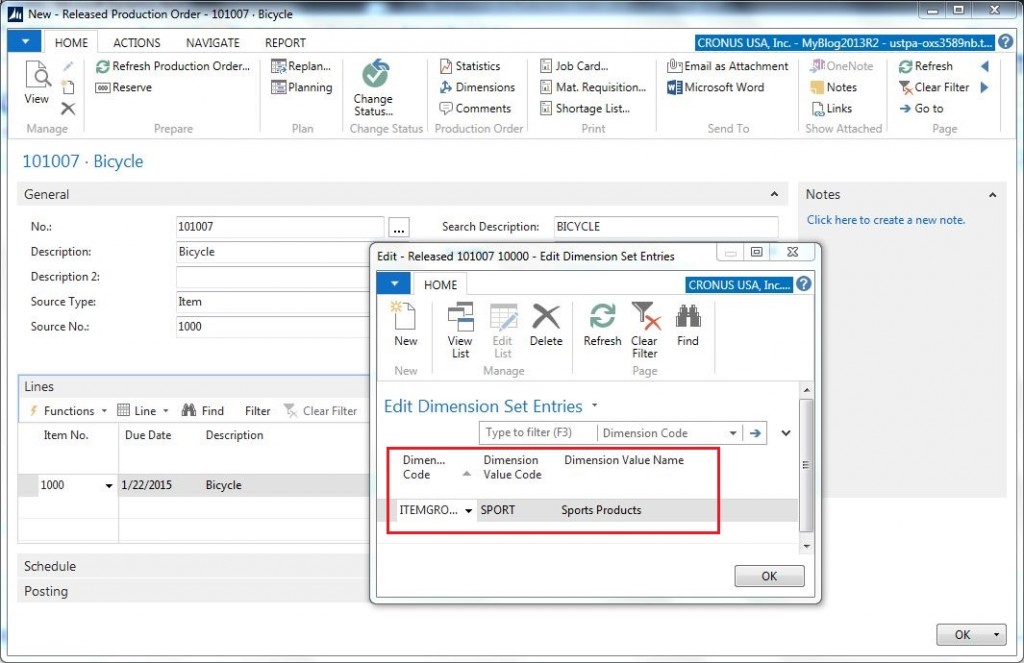

We now create a production order for the bicycle and have a look at where we can see the dimensions. The production order header has the dimensions according to the output item (as expected).

So does the production order line (also as expected).

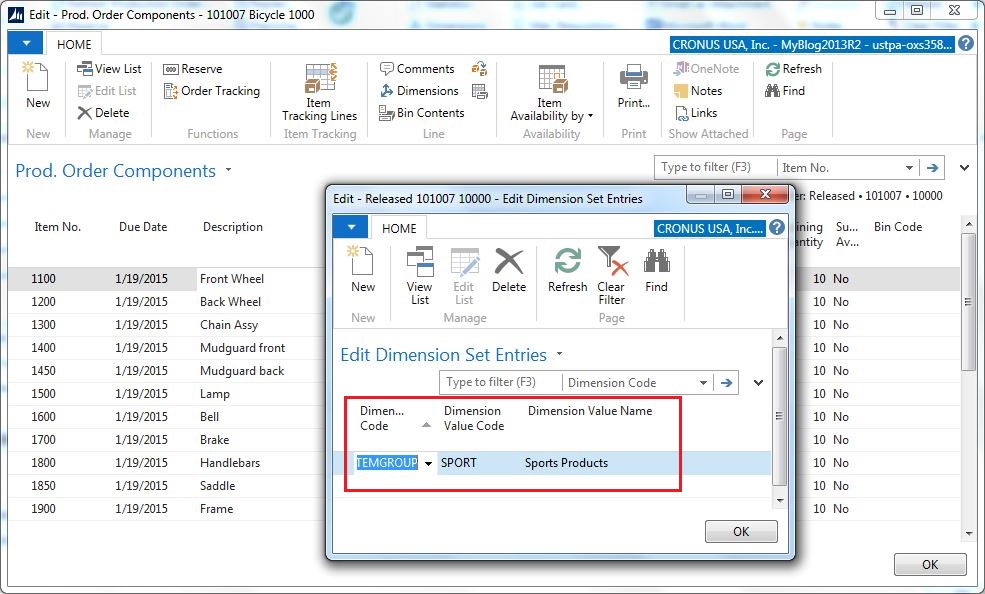

And even the production order components get the dimensions according to the output item (less expected).

This is what can be argued if it is right or wrong since the consumption posting of the components will then get the dimensions according to the default dimensions on the item being produced and not according to the default dimensions on the individual components. Defining the default dimensions on the components with the ‘Value Posting’ equal to ‘Same Code’ will for this reason not work, neither will it work to create reports like inventory value per ‘ITEMGROUP’ since the components inventory in this case will be debited with ‘COMP’ and credited with ‘SPORT’. As long as users are aware of this there will probably not be any issues. If there is, changing the code to use the default dimensions from the component items on the production order components is not too hard (look out for a future blog about this).

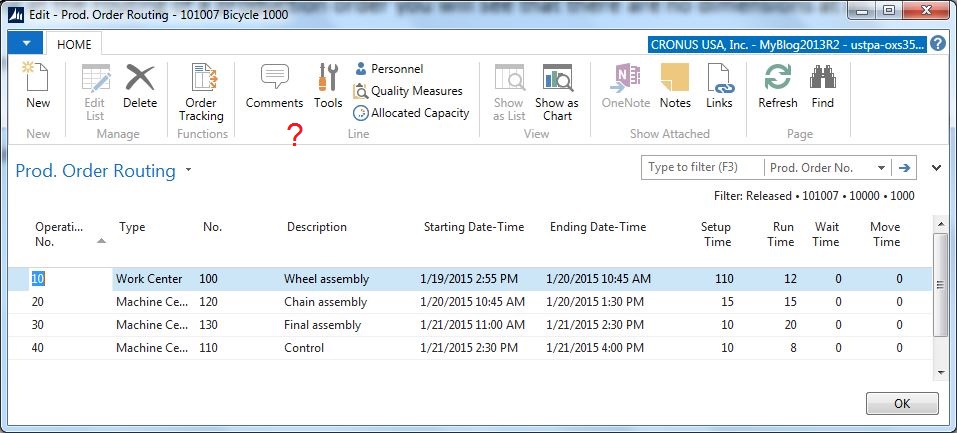

Looking at the routing of a production order you will see that there are no dimensions at all.

This is how it is, although it would have been nice to see and being able to adjust the dimensions on each individual operation in the production order routing.

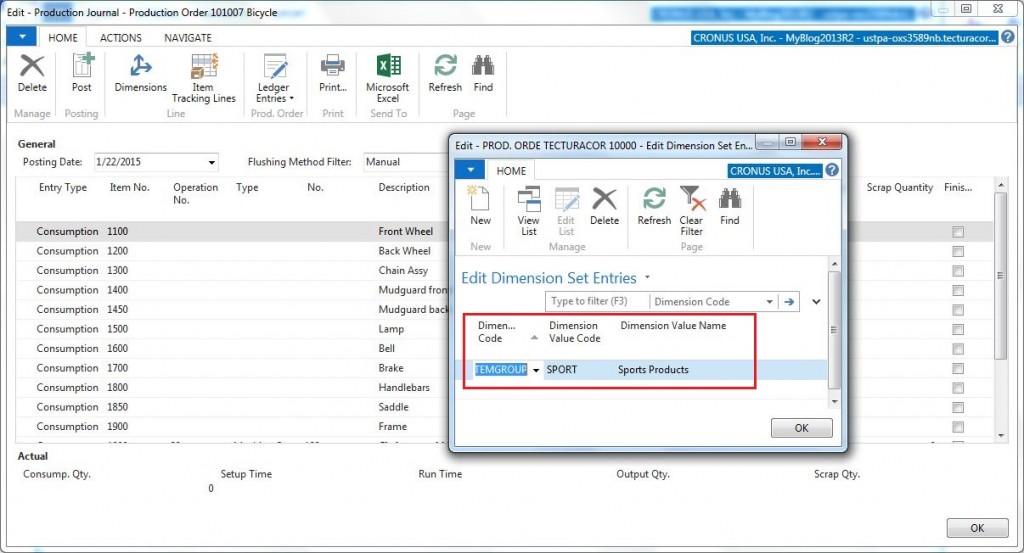

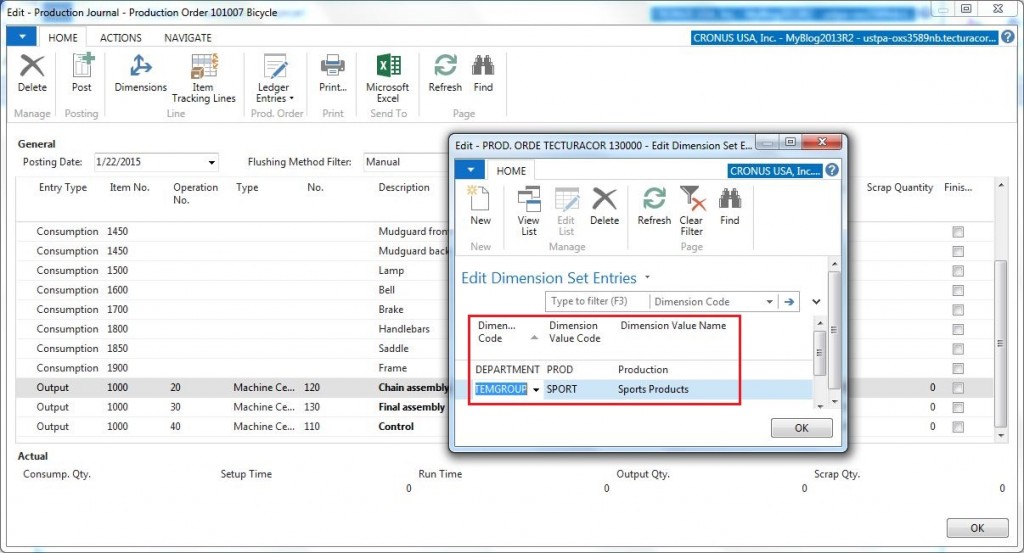

Opening the production journal you will see that the components have the dimensions according to the item being produced (just like on the production order components, so no surprises here).

While the operations have the dimensions as the combination of the dimensions on the production order line and the default dimensions defined on the related work centers (and here it can be changed).

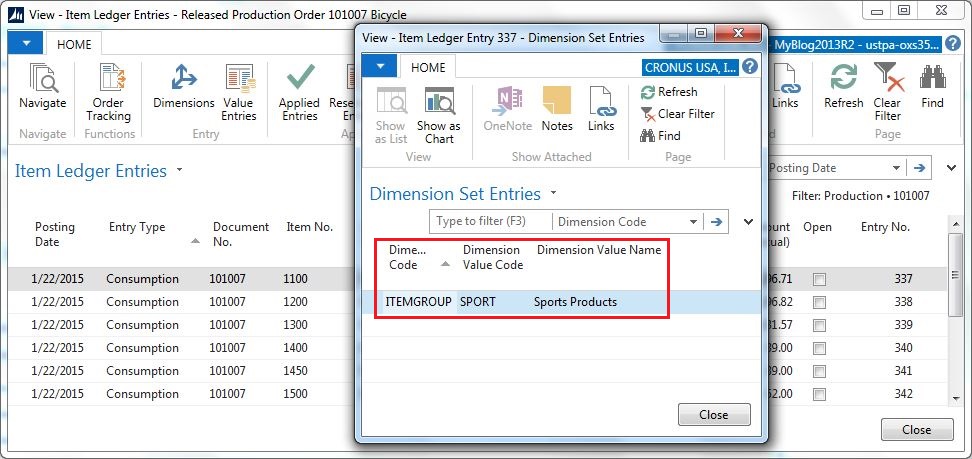

The components are then posted through the production journal (without altering the dimensions in the journal) and all the consumption item ledger entries (and the related value and g/l entries) get the ‘SPORT’ dimension value for the ‘ITEMGROUP’ dimension.

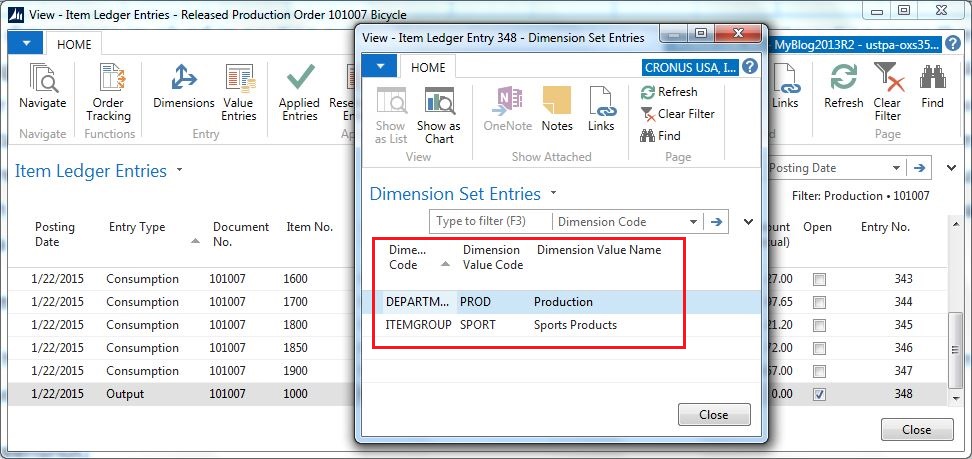

Then the outputs for all operations are posted through the production journal (without altering the dimensions in the journal) and the output item ledger entry (and the related value and g/l entries) gets the ‘SPORT’ dimension value for the ‘ITEMGROUP’ dimension and the ‘PROD’ dimension value for the ‘DEPARTMENT’ dimension (inherited from the work center).

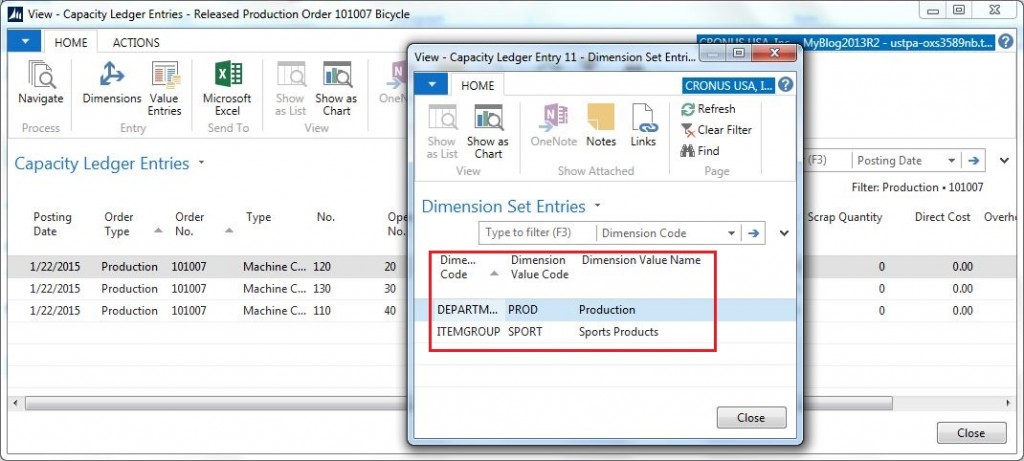

Same dimensions go on the capacity ledger entries (and the related value and g/l entries).

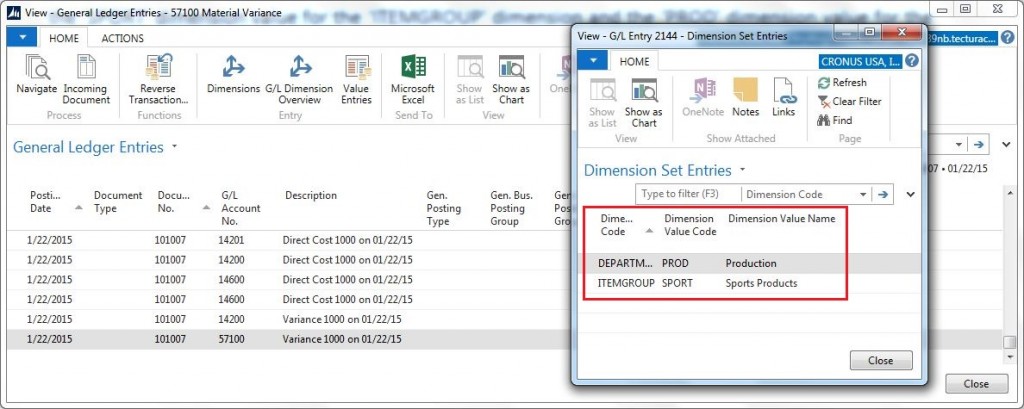

The production order is then changed to finished, being on a standard costing method this calculates and posts the variance into a variance account in the P&L. The variance is posted with the dimensions according to the output (in this case with both the ‘ITEMGROUP’ and ‘DEPARTMENT’ dimensions).

Conclusion

The consumption is posted with dimensions according to the item being produced but without any of the dimensions defined in the work centers. In the general ledger this should only be balance sheet transactions, so not having the department dimension in our case should not be an issue since it is probably more applicable to the P&L transactions.

The output, capacities and variance are all posted with both the dimensions from the item being produced and from the work center (assuming that if you have multiple work centers with different dimension values, then it is the work center on the last operation that controls the dimensions on the output and variance).

On as side note; when creating a production order from a sales order you also get the dimensions from the sales order line on the production order, this is quite nice. 🙂

9 Comments

Leave your reply.