Simple Production with Generic Backflush Routing

You can run production in Microsoft Dynamics NAV with only production BOMs and without any routings. A reason for this is typically that you don’t have a requirement to capture capacity costs (labor and overhead) and you don’t want to do any scheduling of work centers or machine centers. This kind of makes sense because you don’t want to make the configuration in Dynamics NAV more complicated than it needs to be. But one thing that most people forget is that you can only back-flush the output if you use routings in Dynamics NAV. More information about flushing is in one of me previous blog posts; Flushing Methods

With this in mind, sometimes using routings actually simplifies the production process in Dynamics NAV. You can create a generic routing for the only purpose of backward flushing the output and use it for all items where you want Dynamics NAV to automatically post the output when the production order is finished.

Here is an example of how to do this.

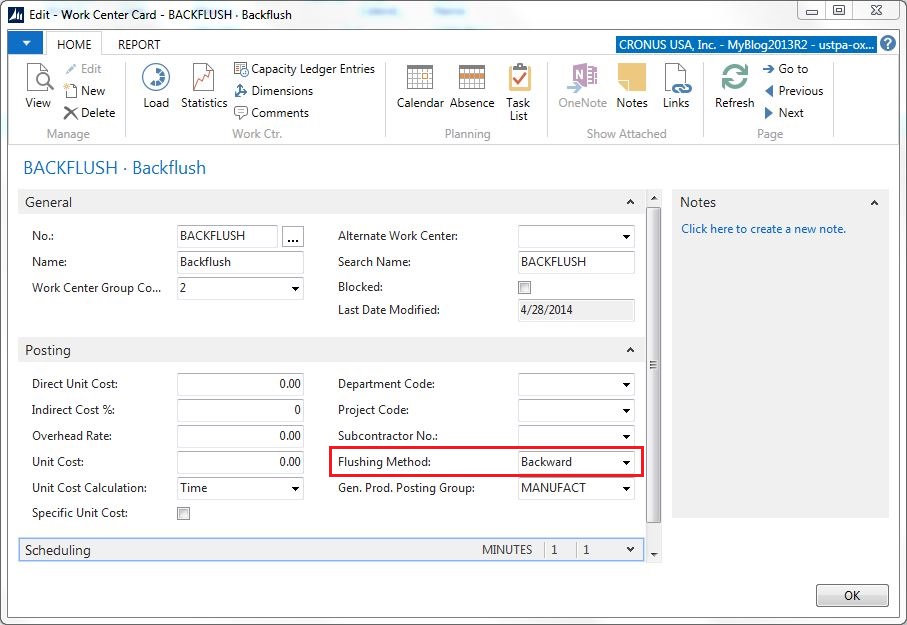

We first setup a new work center just for back-flushing purpose, we call it ‘BACKFLUSH’. The cost fields are left blank and the flushing method is set to Backward.

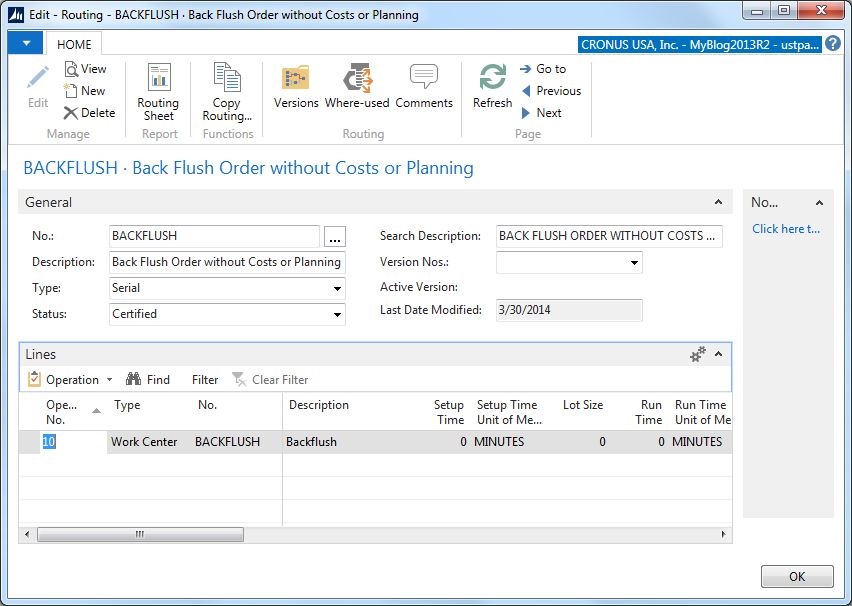

Then we setup a new routing and and this one we also call ‘BACKFLUSH’, The routing has only one operation which is on the ‘BAKFLUSH’ work center we previously created and without any times defined (all 0).

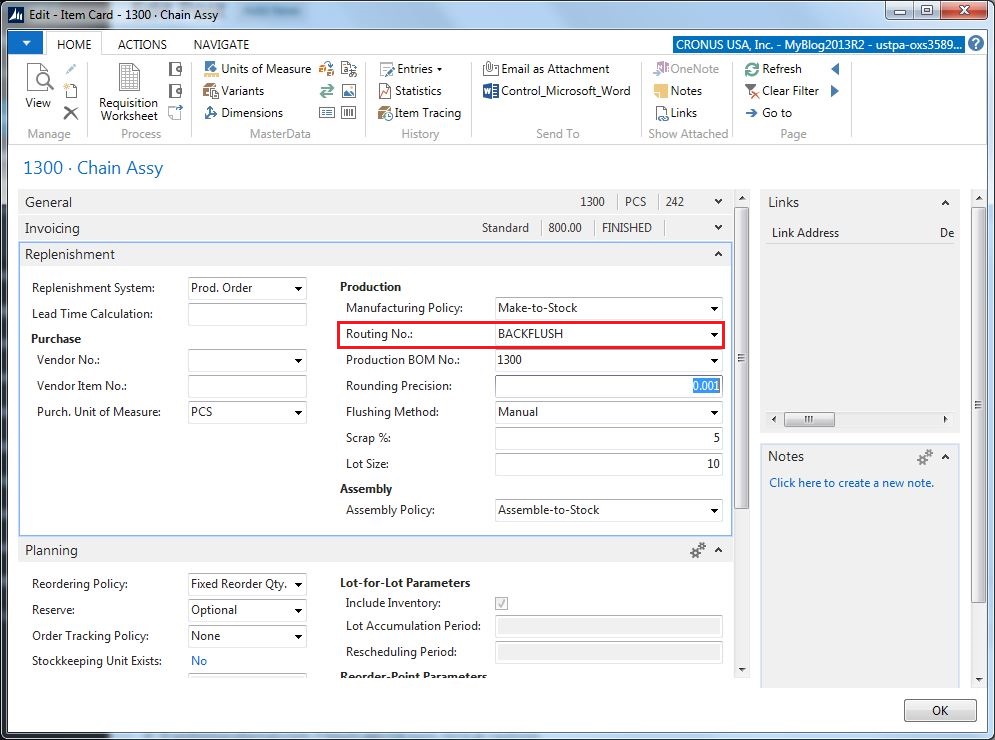

Now we have our generic routing that can be used to back-flush production order outputs if we don’t want any scheduling or capacity costs. We now connect this to the items we want to handle this way, in this example I added it to item 1300.

We also set all the components of to be backward flushed as well (forward flushing could also be used if wanted, then you will have some WIP between releasing and finishing the production order).

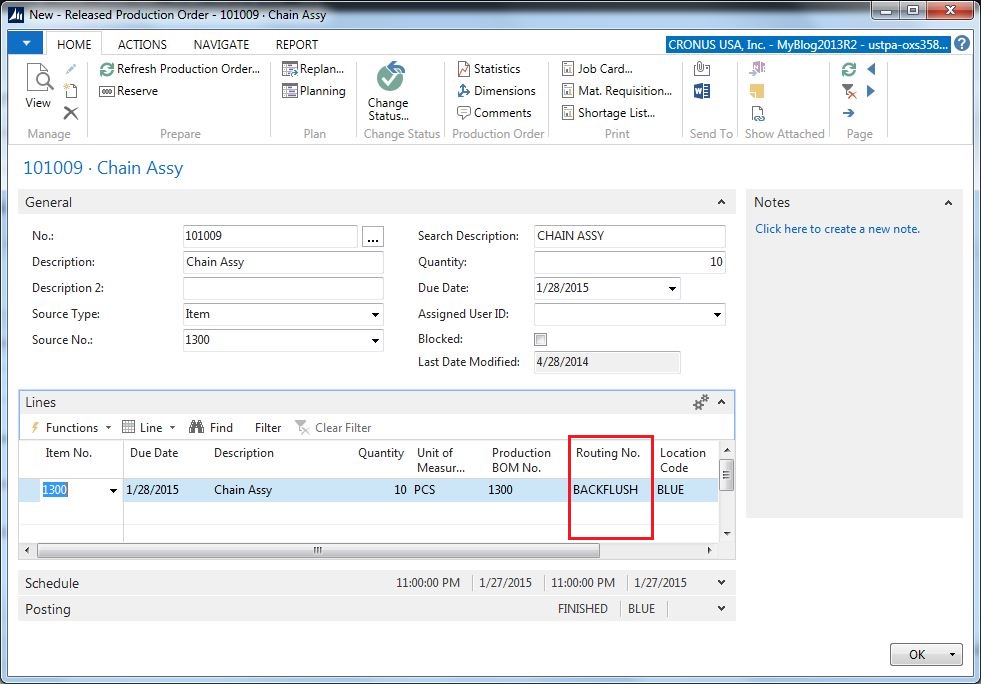

Now we are ready to test it! We create a released production order and can see that the ‘BACKFLUSH’ routing is used.

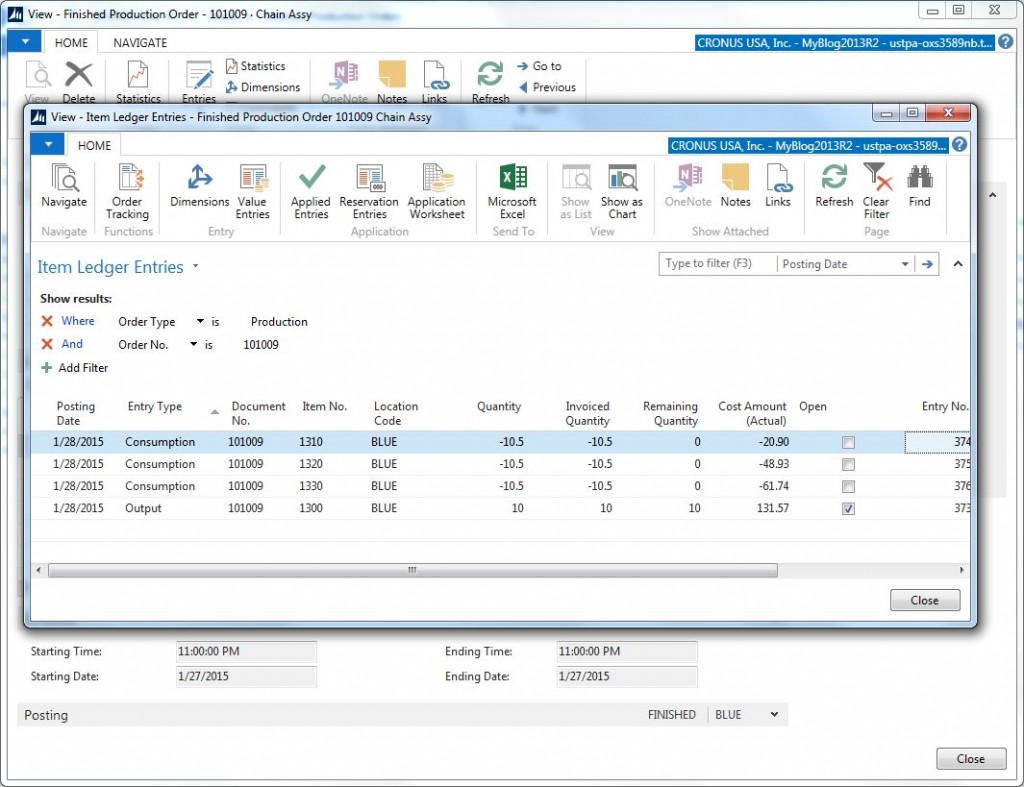

When the production is finished we just change the status of the production order to finished and Dynamics NAV will automatically post the consumption of the components and the output of the finished product without having to do a production journal or output journal. Nice!!

So, the next time you hear that someone wants to use the manufacturing module as simple as possible to just keep track of inventory quantities, then you should think about using a generic routing instead of completely eliminating routings.

This solution works great for discrete manufacturing where the actual consumed and produced quantities are close to the expected quantities (which is very common). Like any other posting of consumption you need to have the components available in inventory and if you user bins they need to be available in the correct bins as well.

Using the Shop Floor Barcode System makes the process even simpler. You can have the production order being created by Dynamics NAV and once completed the users can just scan the barcode on the job card to change the status to finished and Dynamics NAV will handle all the postings. It can not be simpler than this to post production.

4 Comments

Leave your reply.